While shopping for lumber for a dining room table I stumbled upon a board of incense cedar. And the rain stopped, and the clouds parted, and a chorus of angels sang. I had no projects that merited this red and white marbled 1x8. Nevertheless, I left the store with it. (But not with the dining table slab I was looking for. Oh well, I guess I get to take another voyage to the glorious Crosscut Hardwoods in the Georgetown neighborhood of Seattle)

At some point it occurred to me that all the paddles I made are laminations of different species of woods. I have never used just a single board.

Step 1: Layout. I needed to find a way to get a paddle that is 8”wide and 60” long out of a board that was 5”x 96” x 1”

Layout: 1) Cut the board to the shaft length 2) Rip the shaft to wide 3) With the remainder, cut the blade to length 4) Resaw/Split in two the blade to create 2 pieces that are 20” x 3” x 0.5”

Step 2: Crosscut to shaft length of 60”. Not only did this allow me to save 36” of this immaculate board but handling a 5 foot board is a lot easier than an 8 foot one. Especially in my basement shop.

Step 3: Rip. I cut the 2” wide shaft out of the board on the Table Saw. (notice how my workbench acts as a perfect outfeed table)

Ripped to create two pieces: one for the shaft (Right) and a thicker piece that will be split into two for the blade (Left)

Step 4: Crosscut blade to size. Of the 3” x 60” that remained I only needed 20” for the blade. A quick task for the Miter Saw to chop that off.

Crosscut to the length of the blade.

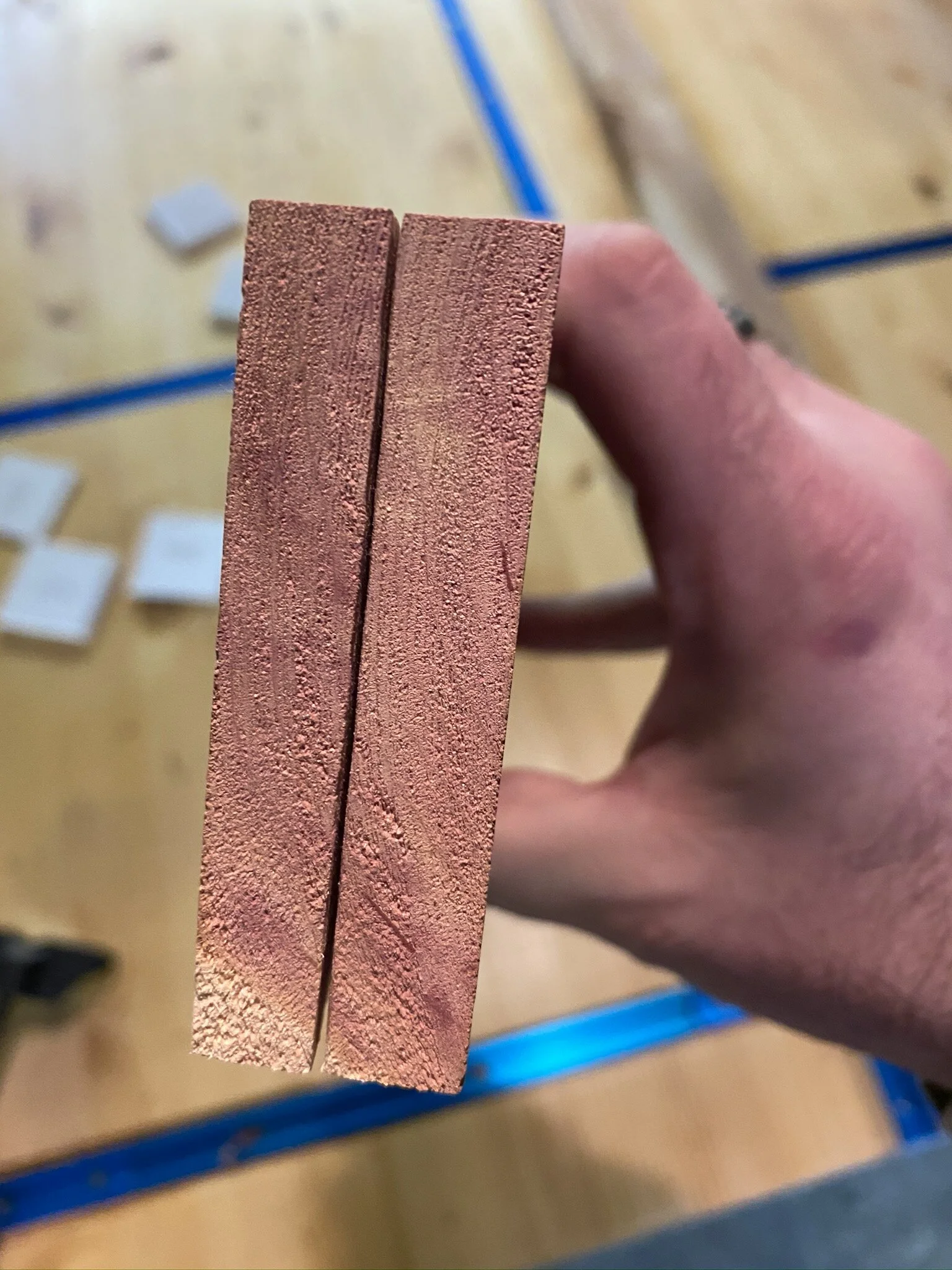

Step 5: Resaw to book-match and thin blade. “Resaw” is the process of cutting a board along its thinnest dimension - like opening up a hotdog bun. I needed the blade to be wider than the 3” I had. Also, I didn’t need it to be 1” thick. So I took it to the Band Saw and split in half. Then I opened it up like a book so that the grain pattern is “book-matched”.

Ultimately I was left with 2 pieces that were 3” x 20” x 0.5” and one that 2” x 60” x 1”. When that was all laid out the blade is 8” (3+2+3) wide and 20” long. And the shaft is 2” wide by 60” long.

In the next post I’ll cover gluing and cutting the basic paddle shape.

One board cut into 3 pieces and layout out.