Monday would come, as it always does, and it was back to the grind. I had nothing to show for my brief reprieve from building robots. Resting in front of the tv did a poor job of resetting a stressful work week. It all blended together. Making stuff is a leisurely activity for me.

The house we were renting in Half Moon Bay had a 2 car garage and, it being California, we didn’t park cars in it. It was used for storage and laundry and to house the kegerator. Furthermore, I have a 100” projector screen. Why not mess around in the garage with the games on?! This is so obvious in retrospect but felt like a profound eureka moment at the time. The kind of realizations that only occur after months of therapy.

Ok. Step one, pick a project and get tools. I had a cordless drill and a hammer. I am handy but my woodworking experience begins and ends with making a Pinewood Derby car in Cub Scouts. Needed to start simple. A chess board! 64 squares, some glue, a few clamps. *aside: it is actually more straight forward than that. Take 4 strips of a light color and 4 of a dark, glue together alternating between the two. Then take that block and cross cut it 7 times to yield 8 strips. Flip over every over one, glue those together and bingo, chess board. All I needed was a Table Saw.

I called my dad to ask if he had advice on buying a table saw. Before he could dispense anything he asked a fair question,

“What are you thinking of making?”

“A chess board”

“Ooooooh. Pretty ambitious first project.”

The hell! It is just a serious of 90 degree cuts. The exact thing a Table Saw is designed for.

I have a great relationship with the ol’ man. But he is a father and I am a son and I couldn’t help but hold contempt for his lack of encouragement. If he thinks a chess board is an ambitious project, well, I’ll show him …

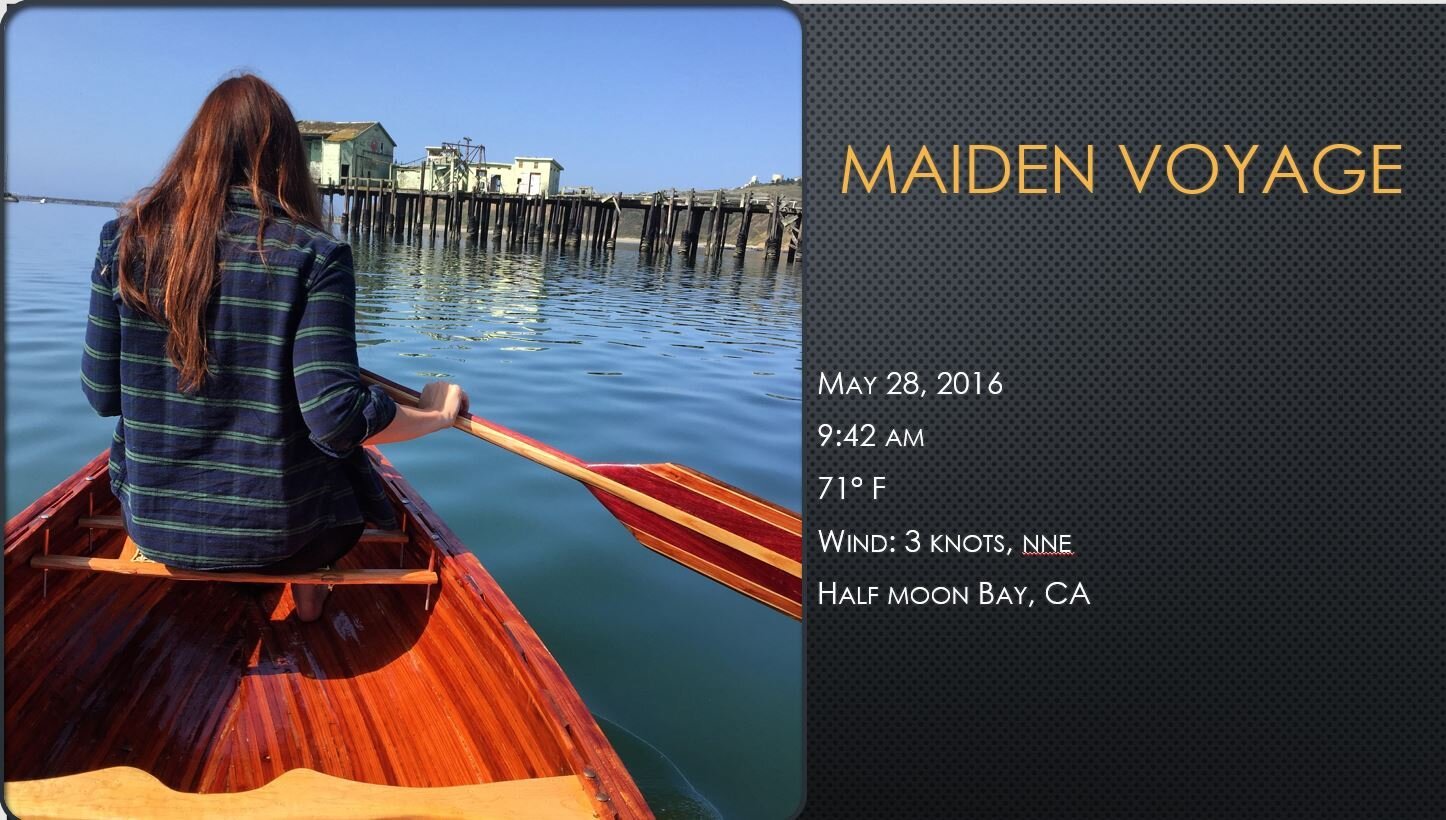

Around the same time I got into the TV Show Parks and Recreation. A character on the show, Ron Swanson played by Nick Offerman, concludes the show by hoping in his canoe and paddling away. That boat was flawless. An idea began to peculate.

Soon after I saw on Twitter that said the canoe in the show was built by the actor. And he had a YouTube series detailing the process. In them he demonstrates the steps outlined in the Bible of woodstrip canoe building - Canoecraft by Ted Moore.

I bought a copy. Read it cover to cover the afternoon it arrived. Read it three more times that week and decided - yup, I can do this. It was beyond my skill set, sure, because, well, I didn’t have a skill set. But the book is so beautifully put together that it breaks down this herculean task into small manageable tasks. What’s the says - How do you eat an elephant … one bite at a time.

March 22, 2015 - Bought a table saw

May 22, 2015 - Bought lumber for the support/assembly frame (i.e. the Strongback). THE BUILD HAD BEGUN

May 28, 2016 - Launched in Pillar Point Harbor

There are few greater joys in the world than accomplishing a long term goal.